Testing iPhone apps is a crucial step in the software development process. This is relatively easy if you’re using Xcode or Apple’s DevKit for iOS. But app testing can be challenging if you don’t have access to an iPhone, iPad, or macOS.

Fortunately, using a simulator to run iOS apps makes it possible to test your app developments on a Windows operating system.

This in-depth guide breaks down the best iOS app simulators on the market today. We’ll cover the top features, benefits, pricing, and other considerations so you can find the best tool for your unique situation.

Before we get started, I just want to quickly clarify the difference between simulators and emulators. These terms are often used interchangeably, but they are not the same thing.

Simulators create an environment that imitates the configurations and behavior of an actual iOS device. Emulators duplicate the software features and hardware of the device in question.

The reviews in this guide will mainly focus on iOS simulators. But some of the tools listed below double as iOS emulators and Android emulators as well. So if you’re looking for a solution that checks multiple boxes, this guide has you covered.

Best iOS Simulators for Windows

- Appetize

- iPadian

- Smartface

- AIR iPhone

- Remoted iOS Simulator for Windows PC

Criteria: How We Chose the Best iOS Simulators

There are dozens of different iOS simulators available on the market today. With that said, not all of them are actually viable options for testing iOS applications.

The five iOS simulators below have been graded based on pricing, features, and functionality.

As previously mentioned, some of them double as emulators for Android devices—making them ideal for those of you who need simulations beyond iOS development.

Unless you’re on a really tight budget, you shouldn’t let pricing alone be the sole factor in your decision. Sometimes paying a little extra will deliver a better experience, which can ultimately translate into a higher quality app. You’ll also want to consider which operating systems the simulators support (Windows 10, Windows 11, etc.).

Let’s dive into the reviews.

1. Appetize

Appetize.io is a web-based iOS simulator and Android emulator that was founded in 2015. For the past seven years, it’s been trusted by hundreds of brands, including Shopify, Intuit, DoorDash, The Washington Post, Ulta Beauty, and more.

What makes Appetize great is its simplicity and versatility. You can use it for training purposes, development, testing, support, and more.

As a web-based tool, you don’t need to download anything to test your iOS app. Just upload the app directly through the website or use the Appetize API for an enhanced workflow with your IDE. Many developers consider it the best emulator and simulator.

Features and Benefits

- User-friendly tool

- Works well for each phase of iOS app development

- Automated testing features

- Stream your app instantly

- Run your app in any browser using HTML with an iFrame

- Supports both iOS and Android

- View remote devices to diagnose problems

- Supports enterprise deployments with SSO, customizations, enterprise-level SLAs

Pricing

There are three different packages to choose from:

Basic — $40 per month

- 20 concurrent sessions

- Standard capacity

- $0.05 per minute rate

- 500 minutes included

Premium — $400 per month

- Unlimited concurrent sessions

- Reserved devices

- $0.05 per minute rate

- 2,000 minutes included

- White label capabilities

Enterprise — $2,000 per month

- Dedicated devices

- Unlimited usage

- White label capabilities

- SSO

- Custom legal agreements

- 24/7 enterprise-grade support

Appetize also offers a free trial package that supports one concurrent session and up to 100 minutes per month.

2. iPadian

Unlike other tools on this list, iPadian is strictly an iOS simulator—not an emulator. So if you’re seeking a tool that does both, you can skip over the section and move on.

That said, iPadian is one of the most popular iOS simulators on the market today. It’s been downloaded more than ten million times and has over one million daily active users.

As a simulator, iPadian mimics the mobile app experience of a real device. This allows you to feel the difference between your iOS app and Android app from a PC or Windows device.

Since iPadian is made strictly for simulations, it does have some limitations. The tool doesn’t create a local version of iOS on your device, and it cannot access the Apple App Store. iPadian doesn’t support iMessaging either.

Features and Benefits

- Ability to run apps including Facebook, Tiktok, Whatsapp, Instagram, and more

- Imitates the appearance, design, and basic features of iOS devices

- Simple and easy to use

- Beginner-friendly

- Affordable

Pricing

iPadian offers one of the best deals for iOS simulation. Just pay a one-time fee of $25 for lifetime access to the tool.

This is a really good price for Windows users who want to have an iOS experience without having to pay for an actual iPad or iPhone. There’s also a free version that works for iOS 10 if you want to try it out before spending the $25.

3. Smartface

Smartface is an emulator and simulator that works for both iOS and Android apps. You can run these apps in your browser without downloading any software or purchasing any additional hardware.

Unlike other iOS simulators and emulators, Smartface supports a wide range of operating systems, devices, and OS versions. Beyond Windows machines, you can run Smartface on Linux, ChromeOS, and macOS as well.

There is a slight catch. Even though this is a browser-based iOS simulator, you can’t just sign up and start using it right away. Smartface requires you to request a demo first, which can be a bit of a pain if you’re trying to do something quickly.

Features and Benefits

- Run iOS apps and Android apps in your browser

- Supports native iOS code in Windows

- Interactive user experience

- Good debugging features

- Supports app testing and development

Pricing

Smartface starts at $99 per month. Again, you’ll need to request a demo before you can access the simulator and emulator tool.

4. AIR iPhone

AIR iPhone is a free iOS simulator for Windows. It runs using the Adobe Air Framework, which means you must install Adobe Air on your machine to run this tool.

The purpose of AIR iPhone is to reproduce an iPhone’s GUI (graphical user interface) without an iOS device.

But compared to other solutions on the market, this tool is outdated and extremely limited. The interface looks more like iOS 3 compared to more recent versions, like iOS 14. While you can see the GUI of an iPhone and iOS application, AIR iPhone won’t actually run the apps as if they were installed on a native iOS device, so it’s not ideal for debugging.

Features and Benefits

- Great if you’re already using Adobe Air Framework

- Free

- Simple installation process

Pricing

AIR iPhone is free to download and use. If you’re on a tight budget and don’t mind sacrificing the quality of your simulator, this tool is fine for basic use.

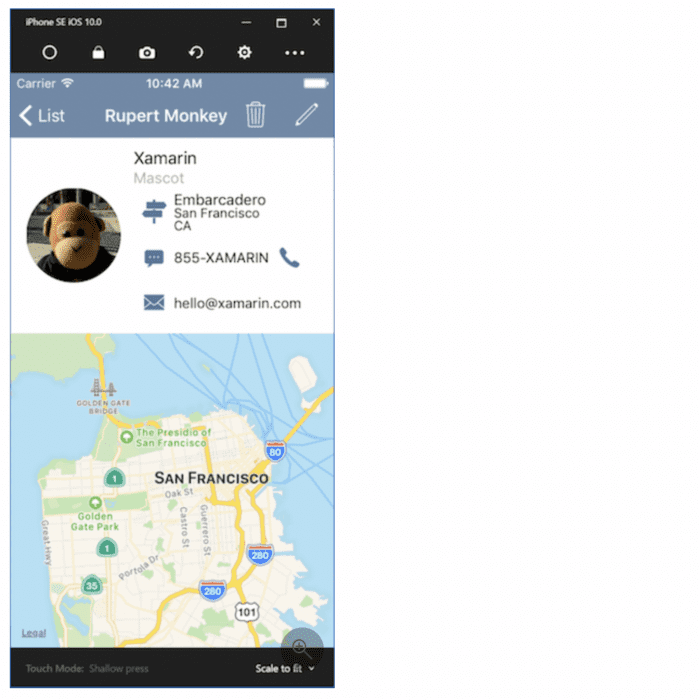

5. Remoted iOS Simulator for Windows PC

Remoted iOS Simulator for Windows makes it possible to test apps using an iOS simulator with Visual Studio 2019 and Visual Studio 2017. The tool is installed automatically with Xamarin with both versions of Visual Studio.

While you don’t need an iPhone or iOS device to run this simulator from Microsoft, you do need a Mac. The tool requires you to pair Visual Studio with a Mac Build host. From there, you can use the simulator for debugging iOS and tvOS projects on a Windows device.

The tool is pretty technical compared to some of the other options on the market, but it works as promised.

Features and Benefits

- Toolbar is user-friendly with lots of options

- Supports iOS functions like Home, Lock, Settings, and Screenshot

- Functionality that mimics Apple’s Touch ID

- Ability to simulate static and moving conditions

Pricing

There are free and paid versions of the Remoted iOS Simulator for Windows. But as previously mentioned, it’s installed automatically when you use Xamarin with Visual Studio.

Conclusion

There are plenty of potential use cases for using an iOS simulator on Windows. The main idea here is to run and test an app without having to buy an iPhone, Mac, or iPad.

If you’re creating an iOS app but don’t own any Apple devices, this is an easy shortcut to testing.

BuildFire has an app emulator built into its software. So you can update your app and see the changes in real-time directly on the screen. Our software also makes it easy for you to check your app directly from your own smartphone. Here are some helpful guides and tutorials on this subject:

- How to Preview Your App On Your Phone

- How to Test Your App With Apple Testflight Before it Goes Live

- How to Publish Your App

But if you’re set on using a third-party tool, that’s fine too. Appetize.io is a great simulator for testing apps. Alternatively, you can use iPadian if you just want to mimic the iOS experience from your Windows computer.